Industrial Engineering

Scope of work

1.Engineering Economics Calculate costs, current rate of return. Machine investment analysis depreciation Analyze decision making under risk

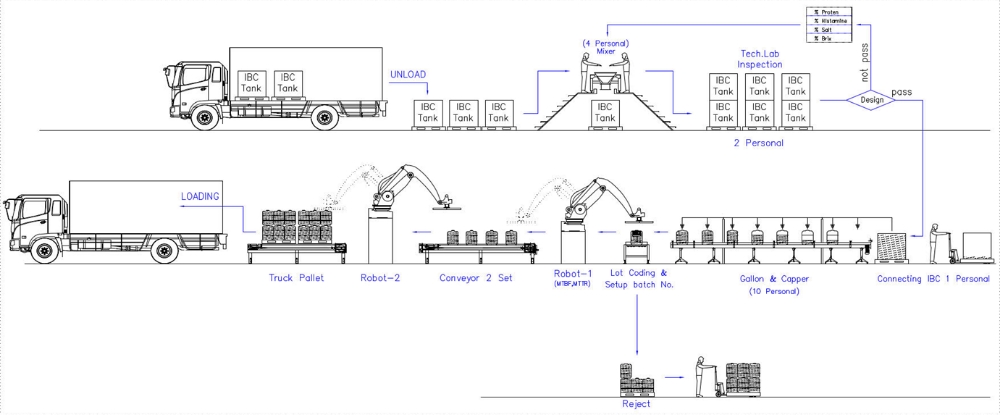

2. Establish production line balance Number of work stations, number of people, study working hours. Set work time standards Calculate lump sum working rates Reduce production costs

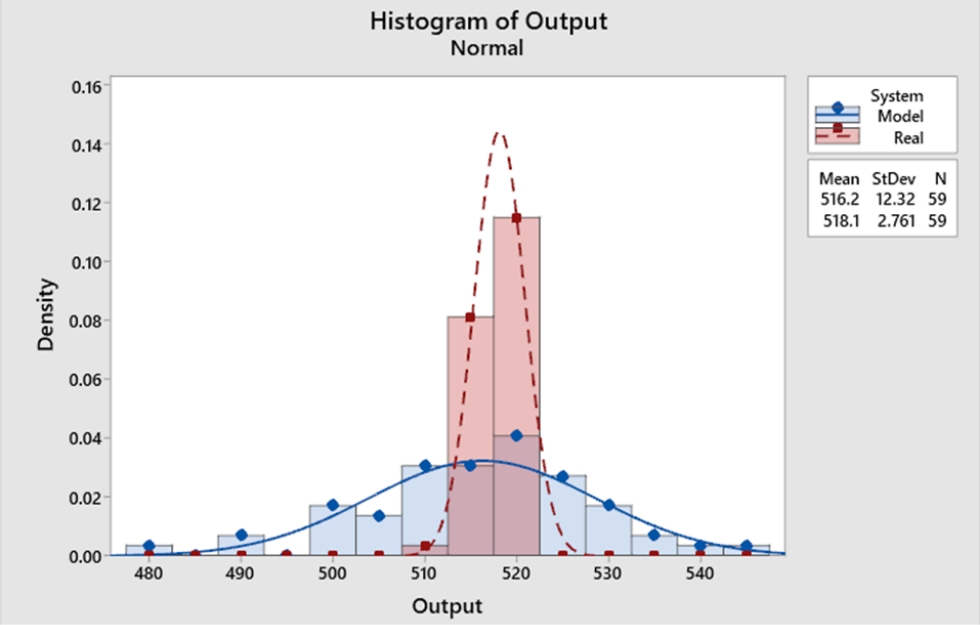

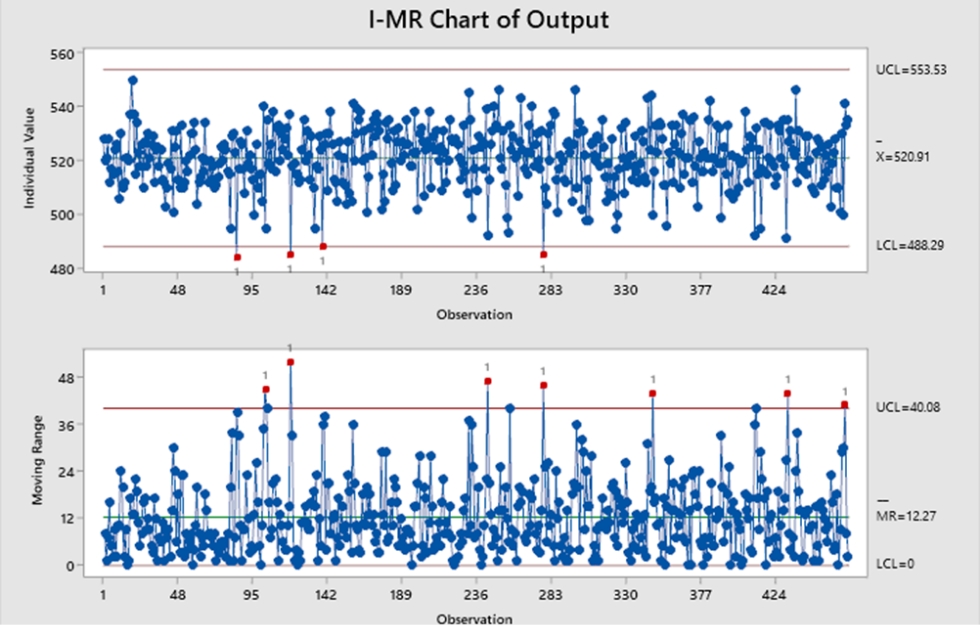

3. Analyze production process performance Analyze production quality, create regression equations to predict the future. Reduce the percentage of damaged products from the process (Waste) by using the MINITAB program.

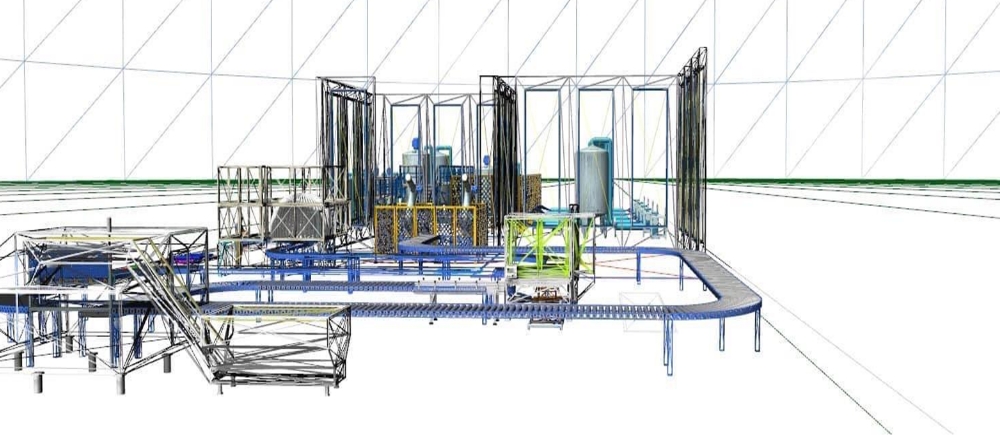

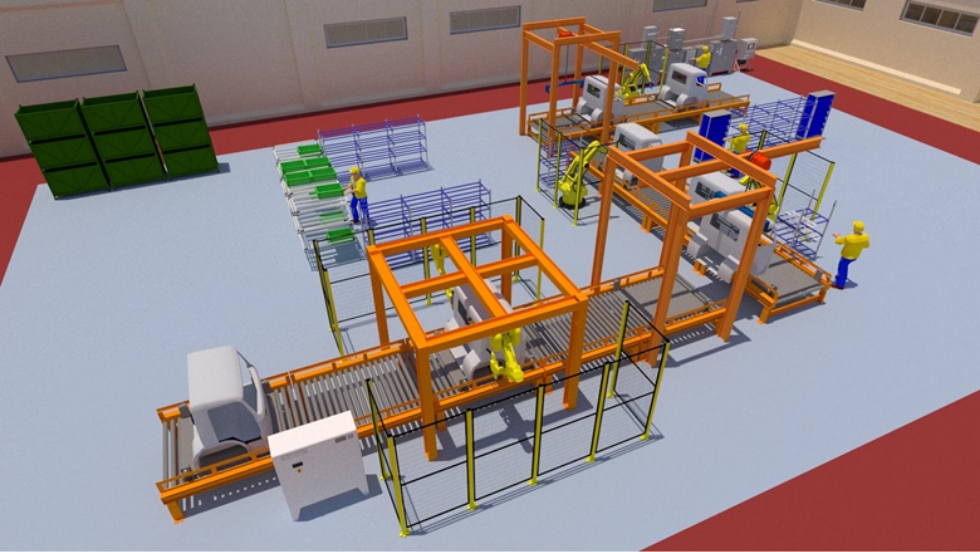

4. Create 2D and 3D production models to analyze bottlenecks for productivity. You can choose more than 3 models before improving the production line or installing new machinery.

5. Plan the installation of new machinery Write CAD CAR CAM factory plans. System lines for good water, waste water, wind, soft water, raw water, steam according to the Department of Industrial Works system.

6. Lay out factory plans according to standards EIT (Engineering Institute of Thailand)

- Industrial factory buildings

- Working environment and safety

- Environment and garbage

- Measurement Prepare reports and submit reports.

- Plan production, analyze Forecasts Seasonal with statistical programs

- Engineer Qualifications Has a professional engineer license. Register with the Council of Engineers.